Analysis of the causes of turbidity in defoaming agents

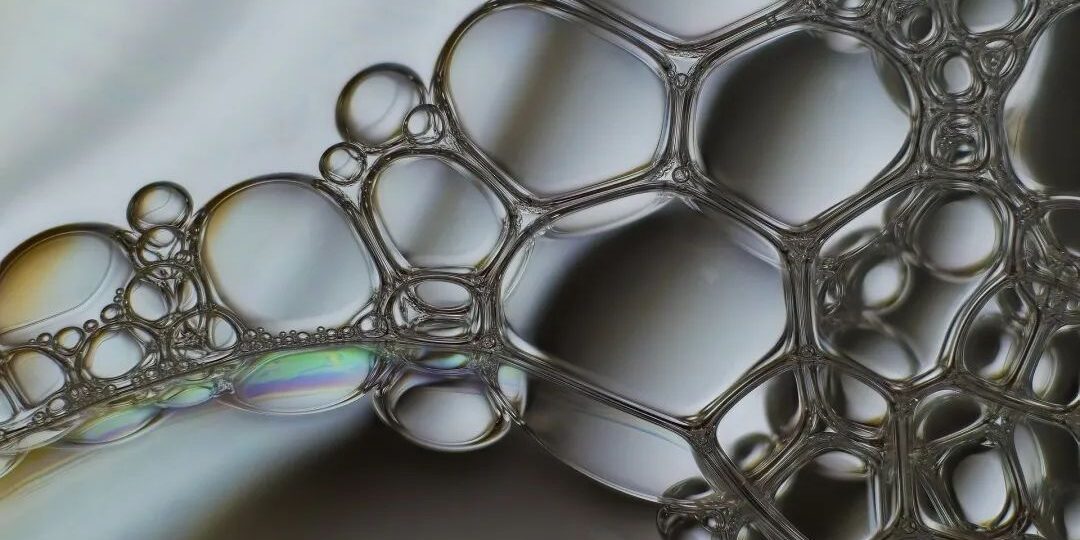

The main components of defoaming agents are generally hydrophobic particles + silicone oil + emulsifier. Hydrophobic particles adsorb silicone oil, allowing the silicone to achieve the maximum effect with as little silicone as possible. Silicone oil, the main defoaming medium, has very small surface tension and is not biophilic. Oil is not hydrophilic and is suspended in the system. When the particle size is near the thickness of the foam wall, it will have no effect if it is too large or too small. Most of them are between 1u-100u and are suspended in the middle of the system. Defoaming agents exist in the foam wall. In the middle, the oil and water phase will be displaced to produce a defoaming effect. At the same time, a small amount of silicone oil will be consumed. When the silicone oil outside the hydrophobic particles is completely consumed, it will be ineffective. However, if the alkali in the system is too high, the defoaming agent will also decompose. Because the synthesis catalyst of the defoaming agent is an acid or alkali emulsifier, its main function is to form small particles of silicone oil.

The problem of defoaming agent turbidity is that the defoaming agent does not exist in the system in a dissolved state in the system, but is usually suspended in the system. Therefore, the amount and quality of the selected hydrophobic particles, silicone oil, and hydrophobic particles must be sufficient. It is important to note that not all defoaming agents can achieve the effect of 575, but generally each has its own advantages and disadvantages, and the understanding of the system is also different. This causes the performance of defoaming agents to vary widely, but as long as the defoaming effect is good, If the foam suppression time is long, there won’t be much of a problem.