How do oil-based defoamers reduce surface tension in foam formation?

The Science Behind Oil-Based Defoamers: Reducing Surface Tension in Foam Formation

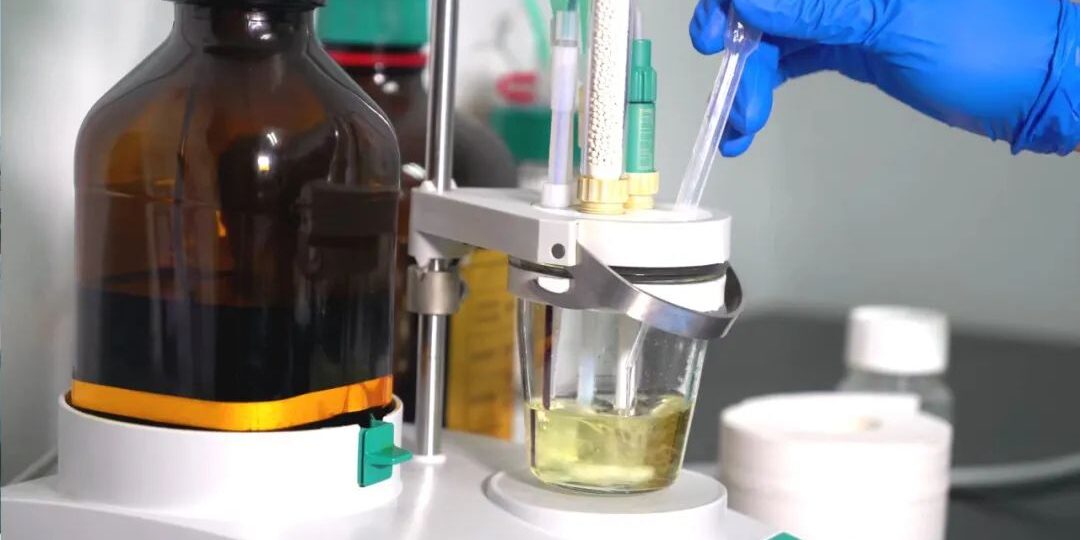

In the battleground against foam during the oil refining process, oil-based defoamers stand out as a significant ally. How they function has much to do with their ability to reduce surface tension — a critical factor that supports foam formation. To understand their mode of action, we need to delve into the science of surface tension and the role oil-based defoamers play in its reduction.

Disrupting Surface Tension: The Role of Surfactants

Oil-based defoamers are composed of surfactants, essential substances that have a profound influence on surface tension. Surface tension is the force exerted by liquid molecules at the surface that pulls these molecules into the bulk of the liquid, resulting in a ‘skin’-like layer. Surfactants in defoamers reduce this tension between the liquid and gas phases in a foam.

Surfactants achieve this by being amphiphilic, which means, they possess both water-attracting (hydrophilic) and water-repelling (hydrophobic) properties. The hydrophobic part of the surfactant molecule is drawn to the gas bubbles in the foam, while the hydrophilic part remains in the surrounding liquid. This dual action destabilizes the foam bubbles, leading to their collapse.

Advancing the Collapse of Foam Bubbles

As surfactants decrease the surface tension, the stability of the gas bubbles in the foam is compromised. With a lowered threshold to overcome, the pressure difference between the inside and outside of the bubbles causes them to collapse rapidly, effectively breaking down the foam.

Quick Dispersion for Effective Results

Oil-based defoamers are designed for rapid spreading and quick dispersion across the foam surface. This optimizes their surfactant action, allowing for an accelerated reduction in surface tension and a swift collapse of foam bubbles.

FAQs

-

How do the surfactants in oil-based defoamers reduce surface tension?

- Surfactants in oil-based defoamers are amphiphilic, possessing both hydrophilic and hydrophobic characteristics. The hydrophobic part interacts with gas bubbles, while the hydrophilic part stays in the liquid phase, thereby decreasing the surface tension and destabilizing the foam bubbles.

-

How does the reduction in surface tension lead to the collapse of foam bubbles?

- With lowered surface tension, the pressure difference between the inside and outside of the foam bubbles causes them to collapse rapidly, resulting in the foam’s breakdown.

-

What role does the quick dispersion of oil-based defoamers play in reducing surface tension?

- Quick dispersion allows the defoamers to spread rapidly across the foam surface, optimizing their surfactant action and enabling an accelerated reduction in surface tension and swift collapse of foam bubbles.