How can I determine the compatibility of a defoamer with my specific process fluid?

Determining the compatibility of a defoamer with your specific process fluid is a critical step in ensuring the effectiveness of the defoaming agent and the integrity of the final product. Here are some steps you can take to ensure your selected defoamer is compatible with your process fluid:

1. Understand Your Process Fluid:** The first step is to comprehend the nature of your fluid. Is it water-based or oil-based? What is the pH level? What are its viscosity and temperature during the process?

2. Manufacturer’s Guidelines:Defoamer manufacturers provide detailed guidelines and specifications for each product. These generally include information about compatibility with different types of process fluids. It’s important to thoroughly review these guidelines.

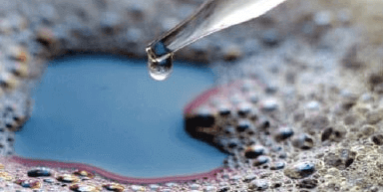

3. Lab Testing: Conducting lab testing on a small scale is an effective way to evaluate compatibility. You can test the defoamer in a controlled environment with your process fluid and observe whether it successfully reduces foam without any unfavorable reactions.

4. Field Trials: Finally, if lab tests are successful, you can perform a field trial using the defoamer in your actual system. Monitor the process and the final product closely to determine if the defoamer is compatible and effective. # Frequently Asked Questions

Q1: Is it safe to use multiple defoamers for one process fluid?

A: Unless otherwise specified by the manufacturer, it is generally not recommended to mix multiple defoamers. Mixing could potentially lead to unforeseen chemical reactions or reduced effectiveness.

Q2: Can I switch defoamers during a process?

A: It’s preferable to avoid switching defoamers mid-process to maintain consistency in your operation. If you need to switch, clean the system thoroughly before introducing the new defoamer.

Q3: What if my defoamer isn’t working as expected?

A: If the defoamer isn’t reducing the foam as expected, it might be due to improper dosage, poor compatibility, or an unsuitable defoamer type for your specific process fluid. You may need to consult with your defoamer provider or a process engineer.

Q4: How do I determine the dosage amount of defoamer?

A: The correct dosage depends on several factors, including the nature of the process fluid, the severity of the foaming problem, and the specific formulation of the defoamer. Your defoamer provider can provide more detailed guidance.

Q5: Are defoamers safe to handle?

A: Although most modern defoamers are safe to handle, always refer to the manufacturer’s Material Safety Data Sheet (MSDS) for detailed information on handling, storage, and emergency procedures. In conclusion, identifying the compatibility of a defoamer with your process fluid requires a combination of understanding your process fluid specifications, following manufacturer guidelines, and conducting thorough tests in both lab and field environments. With the right approach, you can ensure the effective mitigation of foam in your industrial process without any undesired side-effects.