Do you need defoaming agents for food processing?

In the food field, foam is very common, such as beer, tea, etc. On hot summer days or when eating hot pot and barbecue, the foam in the beer can provide a refreshing taste while diluting the bitterness of the beer. Among tea drinks, cloud top is formed by foaming milk and other ingredients. It is a popular type of tea drink that is both beautiful and delicious.

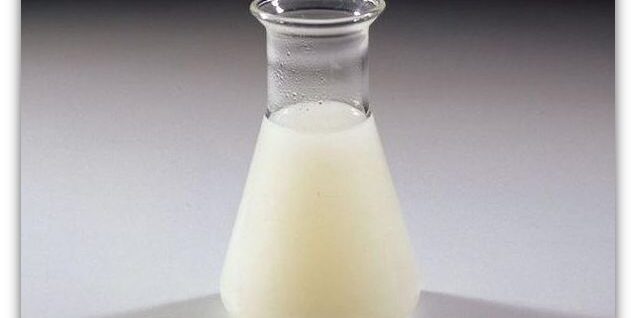

However, in food production, foam will bring some adverse effects, and defoaming agents need to be used to achieve rapid defoaming to meet the needs of food processing and production.

Foam challenges in food applications

If the food contains a lot of protein, sugar, etc., foam will form when air is introduced during the mixing, transferring, and filling processes. Surface-active ingredients such as proteins and sugars will be adsorbed on the surface of the foam, reducing the surface tension of the liquid, causing the foam to become stable and accumulate in large quantities.

Reduce production efficiency

The existence of foam is not conducive to raw material dispersion and product filling, and can easily block production equipment and affect the normal operation of the equipment. Foam accumulation and feeding coefficient affects production efficiency.

Affect the production environment and product quality

Excessive foam will cause overflow, which will pollute the production environment and even cause production accidents. Foam is brought into the final product and will affect product quality.