Composition and effect of special antifoaming agent for electroplating cleaning

Electroplating is a surface treatment process that improves the surface properties of metals by depositing a metal or alloy coating on the metal surface. During the process, metal workpieces need to be cleaned to remove oil stains, oxide films and other impurities on the surface to ensure that the surface of the electroplating substrate is clean. The generation of foam may affect the cleaning effect and equipment operation. In order to solve the foam problem, special antifoaming agents for electroplating cleaning have become a common response.

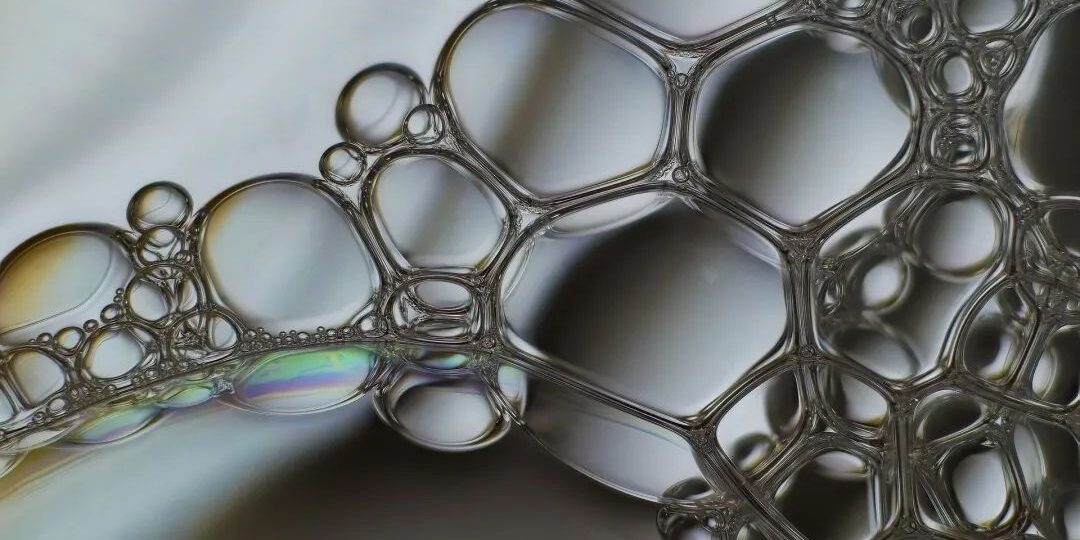

During the electroplating cleaning process, the generation of foam is mainly related to the cleaning agent and cleaning conditions. Here are several possible causes of foam:

1. Surfactants: Surfactants added to the cleaning solution, especially surfactants with good cleaning properties, can reduce the surface tension of the liquid and make it easier for the liquid to wet the metal surface, thereby better removing oil stains and impurities. However, high concentrations of surfactants may cause excessive foam production.

2. Water quality issues: The water may contain some soluble substances, such as hardness substances, chloride ions, etc. These substances react with certain ingredients in the cleaning agent to produce foam.

3. Temperature and pressure: Excessive temperature and pressure may also cause the solubility of gas in the cleaning fluid to decrease, resulting in the formation of bubbles.

Special defoaming agents for electroplating cleaning usually contain the following common ingredients:

Silicone oil substances: Some defoaming agents contain silicone oil substances, which can form a film to cover the foam surface, thereby destroying the stability of the foam and achieving a defoaming effect.

The effect of a special antifoaming agent for electroplating cleaning mainly depends on factors such as the selection and content of the ingredients, the addition method, and the action environment. Generally speaking, defoaming agents can achieve the following effects:

1. Destroy the stability of the foam: Through the action of surfactants, silicone oil and other ingredients, defoaming agents can destroy the stability of the foam film, causing the foam to quickly burst and dissipate.

2. Reduce the formation of foam: The ingredients in the defoaming agent can reduce the surface tension of the liquid, making it easier for the liquid to wet foam and bubbles, thus reducing the formation of foam.

3. Improve cleaning efficiency: The use of defoaming agents can reduce the interference of foam on cleaning agents and cleaning equipment, maintain the cleaning performance of cleaning agents, and improve cleaning efficiency.